Test Setup for the Sharp GP2D12

Distance Measurement Detector

I use the Sharp GP2D12 non-contact infrared distance sensor

for determining the level of salt on the Water Softener Monitor

project. To test the Sharp sensor and to determine the

voltages at particular distances, I created a test apparatus

out of a level and some machined plastic parts. This test

setup is compatible with the whole family of Sharp distance

sensors, which are capable of different measurement distances

and different types of outputs

more

Design and development of a new sensor

system for assistive powered wheelchairs

Abstract. Many disabled people experience considerable

difficulties when driving a powered wheelchair. Disabled people

who are not able to drive a powered wheelchair are seriously

limited in their mobility. Several robotic assistive wheelchairs

have been devised in the past. These wheelchairs are equipped

with range sensors, which detect obstacles and measure the

distance to the closest object. The authors are involved in this

kind of projects but, although many sensors exist commercially,

they never found satisfactory range sensors for wheelchair

applications. After identifying these sensor requirements, this

paper presents the design of an optical ranging system, more in

particular a lidar (Light Detection and Ranging) scanner for

wheelchair applications. Test results are reported to show that

this scanner meets the identified requirements.

Design and development of a new sensor

system for assistive powered wheelchairs

Abstract. Many disabled people experience considerable

difficulties when driving a powered wheelchair. Disabled people

who are not able to drive a powered wheelchair are seriously

limited in their mobility. Several robotic assistive wheelchairs

have been devised in the past. These wheelchairs are equipped

with range sensors, which detect obstacles and measure the

distance to the closest object. The authors are involved in this

kind of projects but, although many sensors exist commercially,

they never found satisfactory range sensors for wheelchair

applications. After identifying these sensor requirements, this

paper presents the design of an optical ranging system, more in

particular a lidar (Light Detection and Ranging) scanner for

wheelchair applications. Test results are reported to show that

this scanner meets the identified requirements.

Sensor design

An approach that is now feasible at a modest price

tag, is using a lidar scanner (Light Detection And

Ranging). Various systems already exist on the market

that use light instead of the microwaves of the well

known radar. A lot of research has been done on range

finders, anti-collision systems for the car industry and

pollution surveillance systems. Most of these systems

use large aperture optical telescopes, powerful lasers

and ultra fast electronic devices for the processing of

the data to determinate the time of flight of the emitted

and reflected light. They have a range of several hundred

metres up to a few kilometres. This performance

is much too high and most of these systems are rather

bulky and very expensive and are not always eye-safe.

All these factors exclude their use on a wheelchair.

The range of the obstacle detection system is from zero

up to 4 m. The determination of the time-of-flight in

this range, calls for ultra fast electronics (660 ps time

resolution for a spatial resolution of 10 cm) and puts

a high demand on the switching characteristics of the

opto-electronic components.

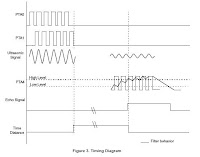

In order to keep the complexity of the system, the demand

on the opto-electronic components and the price

tag low, it is proposed to substitute the direct timeof-

flight measurement by the measurement of a phase

shift. The light from an infra-red laser diode is amplitude

modulated with a signal of 5–20 MHz, depending

on intended range or resolution. The difference in

phase between the signals from the transmitted and re-

flected light is directly proportional to the distance. The

advantages of this method are the much lower switch

frequency, the lower data processing speed and the use

of less exotic components. The disadvantages are the

longer time it takes to get the measurement (some microseconds),

compared to the time-of-flight measurement

(some nanoseconds). This is only important in

3D scanning systems where data throughput must be

very high. If the signal-to-noise ratio does not enable

a stable measurement, the bandwidth of the processing

circuit must be further reduced, increasing processing

time. This is not necessarily a drawback in wheelchair

applications because the sample rate can still be suffi-

cient high. Scanning in a horizontal plane can be performed

by a rotating mirror, reflecting transmitted and

received beams, or by rotating optics. The scanning

rate of the lidar amounts to 5 rev/s.

Different modules for the lidar scanner have been

developed:

An approach that is now feasible at a modest price

tag, is using a lidar scanner (Light Detection And

Ranging). Various systems already exist on the market

that use light instead of the microwaves of the well

known radar. A lot of research has been done on range

finders, anti-collision systems for the car industry and

pollution surveillance systems. Most of these systems

use large aperture optical telescopes, powerful lasers

and ultra fast electronic devices for the processing of

the data to determinate the time of flight of the emitted

and reflected light. They have a range of several hundred

metres up to a few kilometres. This performance

is much too high and most of these systems are rather

bulky and very expensive and are not always eye-safe.

All these factors exclude their use on a wheelchair.

The range of the obstacle detection system is from zero

up to 4 m. The determination of the time-of-flight in

this range, calls for ultra fast electronics (660 ps time

resolution for a spatial resolution of 10 cm) and puts

a high demand on the switching characteristics of the

opto-electronic components.

In order to keep the complexity of the system, the demand

on the opto-electronic components and the price

tag low, it is proposed to substitute the direct timeof-

flight measurement by the measurement of a phase

shift. The light from an infra-red laser diode is amplitude

modulated with a signal of 5–20 MHz, depending

on intended range or resolution. The difference in

phase between the signals from the transmitted and re-

flected light is directly proportional to the distance. The

advantages of this method are the much lower switch

frequency, the lower data processing speed and the use

of less exotic components. The disadvantages are the

longer time it takes to get the measurement (some microseconds),

compared to the time-of-flight measurement

(some nanoseconds). This is only important in

3D scanning systems where data throughput must be

very high. If the signal-to-noise ratio does not enable

a stable measurement, the bandwidth of the processing

circuit must be further reduced, increasing processing

time. This is not necessarily a drawback in wheelchair

applications because the sample rate can still be suffi-

cient high. Scanning in a horizontal plane can be performed

by a rotating mirror, reflecting transmitted and

received beams, or by rotating optics. The scanning

rate of the lidar amounts to 5 rev/s.

Different modules for the lidar scanner have been

developed:

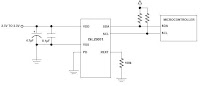

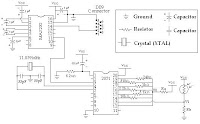

– aspheric lens design for optical transmitter and

receiver,

– laser diode output stage (transmitter),

– PIN diode preamplifier,

– limiter and phase measurement (distance measuring),

– microprocessor and interface,

– scanning system.

More pdf